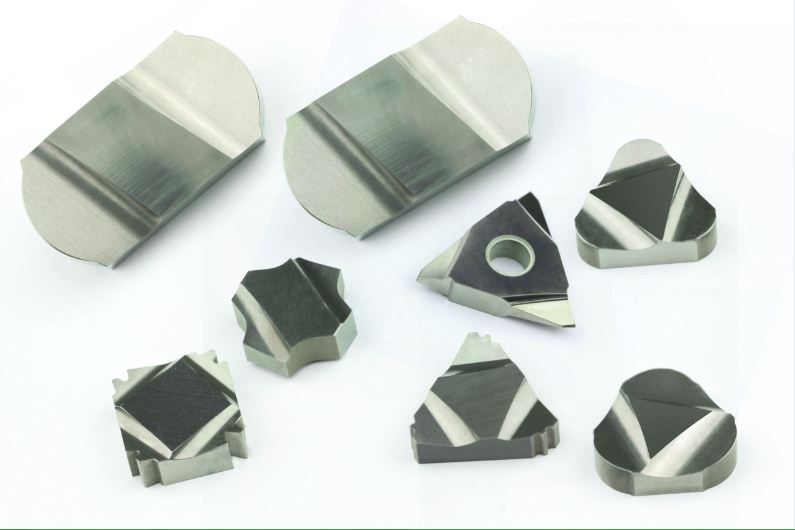

Cermet bearing cutting tools

Cermet bearing cutting tools

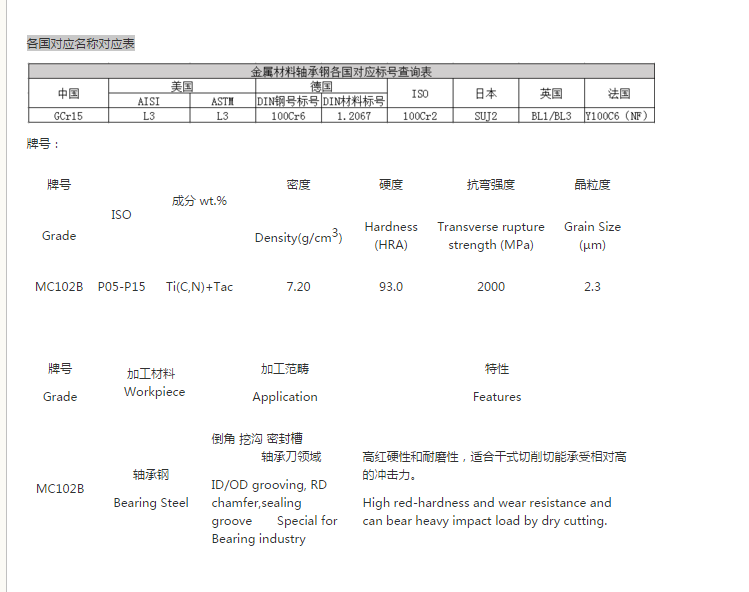

Cermet is a kind of cutting tool material whose properties and application range are between ceramic and cemented carbide. It overcomes the ceramic strength, toughness and a disadvantage of low plastic deformation resistance, high hardness, low density with ceramic, small friction coefficient of steel, oxidation resistance, acid and alkali corrosion resistance, and resistance to adhesive wear and tear when cutting and chemical diffusion wear resistance is good wait for a characteristic, at the same time also have cemented carbide with high intensity, strong shock resistance characteristics. Since its birth in the early 1970s, it has been considered as a kind of tool material with broad development prospects. Some industrial developed countries have carried out a lot of basic research and development work, launched a series of varieties and brands, and widely used in metal cutting tools, wear parts and seals and other fields.

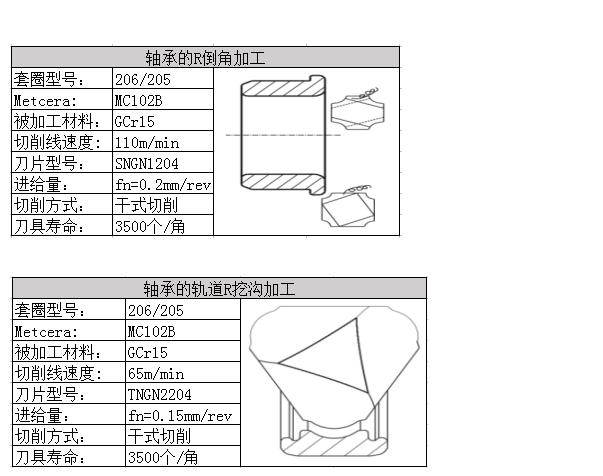

In the bearing car processing industry, for the groove, sealing groove, chamfering car processing generally adopts the forming tool, the workpiece material is GCr15, annealing hardness HB179 ~ 207, dry cutting (air-cooled). Since the hardness of the workpiece material and the cutting speed have a great influence on the tool life, combining with the tool material, the recommended cutting speed Vc for continuous dry cutting is 65 ~ 110m/min.

Because this kind of tool for large cross-section shape, the shape precision demand is higher, at the same time in order to ensure the efficiency, reduce the knife of time, needs to have high tool life, metal ceramic meet the requirements of the field, because it not only has good red hardness at high temperatures, can under the condition of dry cutting, bring the ultra high surface finish and long service life of cutting tools, so the cutter has higher cost performance.

Recommendation: MC102B brand specially developed by Mercure for bearing processing field.